Dicing is a culinary cut that creates uniform, bite-sized pieces. Using a knife, dicing allows food to cook more evenly and has a more polished look.

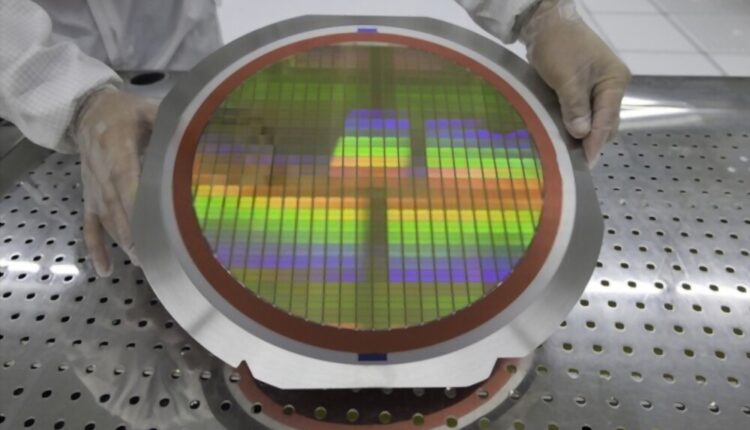

Silicon carbide is a promising material for applications such as radio frequency and high-power devices. However, traditional dicing of SiC wafers has problems such as mechanical breaking and debris contamination.

Meaning

Whether it’s cutting ingredients into uniform shapes or creating aesthetic salads, dicing is an essential culinary skill. The technique offers numerous benefits beyond making food look great, including allowing the flavors of ingredients to meld more easily and improve their overall flavor. Dicing also makes cooking more efficient, as it allows ingredients to be cut into small pieces that cook more quickly and evenly.

Dice have been around for thousands of years, and their history stretches as far back as ancient Egypt and the Middle East. Although the cube-shaped six-sided die eventually became the most common type of dice, other forms were used throughout history, such as two-sided or four-sided dice in ancient China and the Middle East.

As the number of dice rolls in gambling games became more regular and standardized, gamblers began to pay more attention to the likelihood that a particular roll would occur, instead of believing that Lady Luck was influencing their odds of winning. This shift in thinking ultimately led to the development of probability theory.

Copyright TechPlanet.today

In semiconductor manufacturing, wafer dicing is a crucial process that separates individual integrated circuits or chips from a single silicon wafer. The process requires precise control to ensure that the chips are separated correctly, with no chip damage or contamination. This is especially important for advanced semiconductor devices, which contain multiple layers of transistors, resistors, capacitors, and interconnects. In addition, wafer dicing is often performed in high-temperature environments and under tight tolerances.

Different dicing techniques are suitable for different materials, depending on their hardness, brittleness, and thermal sensitivity. For example, blade dicing may be suitable for silicon wafers, but it can cause chipping or cracking in more brittle or fragile materials such as gallium arsenide. On the other hand, laser and plasma dicing are non-contact methods that can minimize mechanical stress and prevent damage to delicate dies.

Purpose

When dice are tossed, they generate a random result—most commonly a number or sequence of numbers. Dice have been around for most of recorded history, used for everything from board games to divination to gambling. Their precise origins are unknown, but they’re an example of human ingenuity.

Most modern dice are cubical cubes with six sides, each bearing a number from one to six. They may also have additional markings, such as letters for Boggle or directions for Warhammer Fantasy Battle. Dice with different shapes—slab, octagonal, or a polyhedral—are also available for other applications.

In ancient times, most dice were made of stick, shell, or seed and were two-sided with one flat side and one rounded side. These were usually painted or carved to differentiate them from each other. The ancients believed that the way a die fell was determined by the indirect actions of gods and supernatural forces.

While the earliest dice were probably hand-made, they later became mass-produced and more affordable. The advent of machine cutting and polishing methods reduced the cost even further. Today, there are a wide variety of dicing blades and processes. Each has its own unique advantages and disadvantages.

Using a proper feed rate is another important factor in achieving the desired dicing quality. Feed rates that are too fast can cause excessive chipping, which can increase waste and decrease the overall efficiency of the dicing process. In order to avoid this, it’s best to use a feed rate that is optimized for the specific material being cut. In addition, the use of short pulses of laser energy, such as femtosecond or picosecond lasers, can reduce the risk of thermal damage to delicate semiconductor materials.

Techniques

For chefs, the cut of an ingredient is one of the most important factors to consider in a dish. It not only affects appearance but also the cooking process and flavour. For that reason, chefs use a number of different dicing techniques to produce the desired results.

The first step of dicing involves cutting the food into long, thin strips. This is known as julienne and can be done using either a chef’s knife or a paring knife. Once the julienned food is uniform, it’s then diced into small cubes. The Brunoise cut is a popular choice for this, as it produces smaller pieces that are 3mm x 3mm in size. This is a perfect choice for ingredients with a crunch, such as carrots or onions.

Aside from adjusting the feeding rate to match the cutting material, the blades also need to be dressed regularly to ensure that they are sharp and will provide high-quality cuts. The dressing process helps to eliminate issues like burrs, cracks, nonlinearity, subsurface damage, and chipping. Moreover, it can reduce the amount of cooling water and scraps generated by the dicing process.

In addition to using the right blades and feed rate, it is also essential to select the correct mounting method. Choosing the wrong mounting media can lead to poor quality cuts, as well as increased die rejection rates. It’s important to choose the best mounting method for your application and understand how to optimize it. This will help you achieve the best possible dicing quality and productivity.

Applications

First of all, Wafer dicing is an essential manufacturing process that separates individual integrated circuits (ICs or chips) from a semiconductor wafer. This step is vital for the production of high-performance, smaller electronic devices, and requires precision and accuracy to ensure a high yield of functional, undamaged chips.

Various dicing techniques exist, and each has its own advantages and disadvantages. Choosing the right one depends on the material, dimensions, and geometry of the individual chips. For example, blade dicing may be more cost-effective for larger chips with simple geometries, but it can cause chipping or cracking in more fragile materials like silicon. On the other hand, laser dicing and plasma dicing are non-contact methods that minimize mechanical stress.

In addition to ensuring precision and accuracy, dicing processes must also be free of contaminants and residues. Incorporating cleaning steps within the dicing process is one way to achieve this goal. Another is using cleanroom facilities and equipment, which help reduce the presence of airborne contamination.

The use of a femtosecond or picosecond laser can also significantly improve the efficiency and quality of the dicing process. These lasers generate ultra-short pulses of light, which allow them to cut through semiconductor materials with minimal heat generation. This helps to minimize the risk of thermal damage to delicate device structures, and it also allows for faster processing times.

In case you have found a mistake in the text, please send a message to the author by selecting the mistake and pressing Ctrl-Enter.

#Art #Dicing #Exploring #Meaning #Applications